blow molding machine parts name

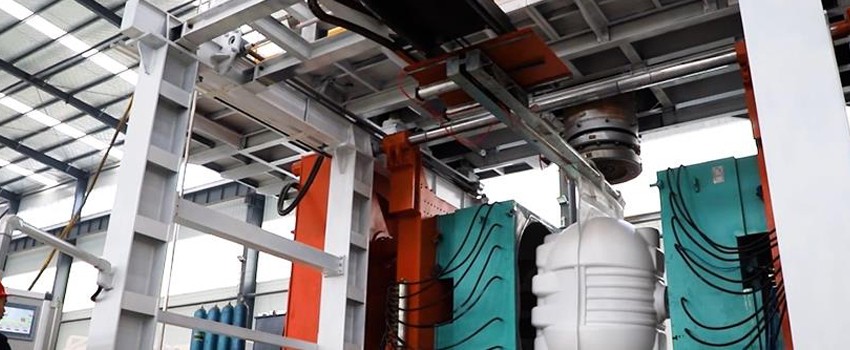

Extrusion blow molding machine. All of our blow molding machines are made to last are easy to use and offer quality production.

Extrusion Blow Molding Machine Parts Name What Do Parts For The Machine

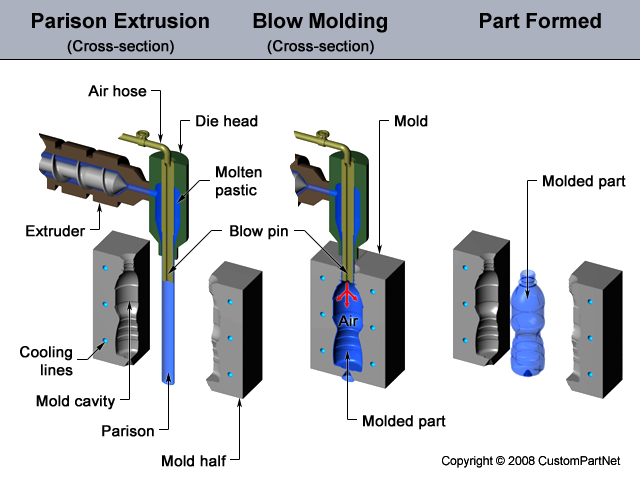

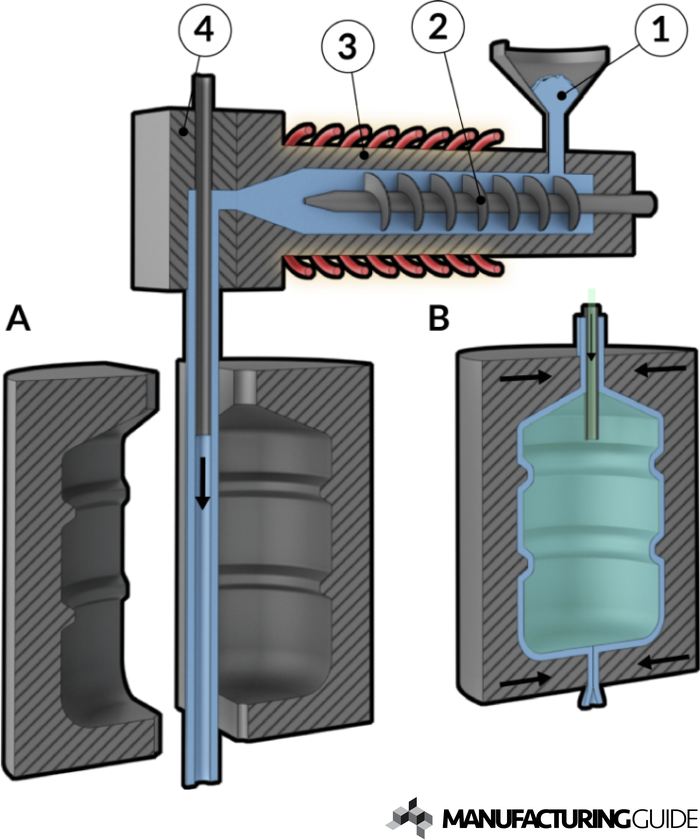

The tube of melted plastic resin formed by the blow molding die.

. In addition controlled by electric motor the FE. Compare this product Remove from comparison tool. Bottle Cutting And Packing Machine.

Extruder is simply a machine which consists of cylinders and barrels where the plastic is to be heated up. Blow molding or moulding is a manufacturing process for forming and joining together hollow plastic parts. Poor mold surface n Refinish a poor or worn mold surface.

Up to 24 cash back Blow Molding Machine the basic information Blow molding machine also known as hollow blow molding machine a kind of rapid development of plastic processing methods. The first part of blow molding involves working with tubes of molten plastic. Browse our selection of used blow molding machines.

Low density Polyethylene LDPE High Density Polyethylene HDPE Polypropylene PP Polycarbonate PC Polystyrene PS Co-polyester Polyethylene Terephthalate PET Polyvinyl Chloride PVC Nylon Acrylonitrile Butadiene Styrene ABS are the main resins utilized with blow molding. Controlling the parison to extrude uniformly and controlling the wall thickness of the extrusion parison to. Thermoplastic resin by extrusion or injection molding of plastic parison tube hot or heated to softening state put in split cavity mold closing immediately after ventilation with.

Parts of Blow Molding. Zhangjiagang Apollo Machinery Co Ltd ONPLAS Group located in the city of Zhangjiagang which lies conveniently near to the biggest city of ChinaShanghai. Pressurized air flows through the blow pin to inflate the parison.

Extrusion Blow Moulding Machine. Mold and the blow molding process. Pneumatic Blow Molding Machine.

The parison is extruded vertically between the two open mold halves so they can close on the parison and blow pin. Energy savings low maintenance higher cavitation and quick changeovers are the attractions cited for this new reciprocating-screw bottle machine said to be the first. Each blow molding machine is made to change with your business.

Plastic Injection Moulding Machine. Injection blow molding - The molten plastic is injection molded around a core. Hydraulic Blow Molding Machine.

Prompt response with spare parts. 0 l - 2 l. Disposable plastic straw pipedropper is widely used in laboratory food research medical industrial etc.

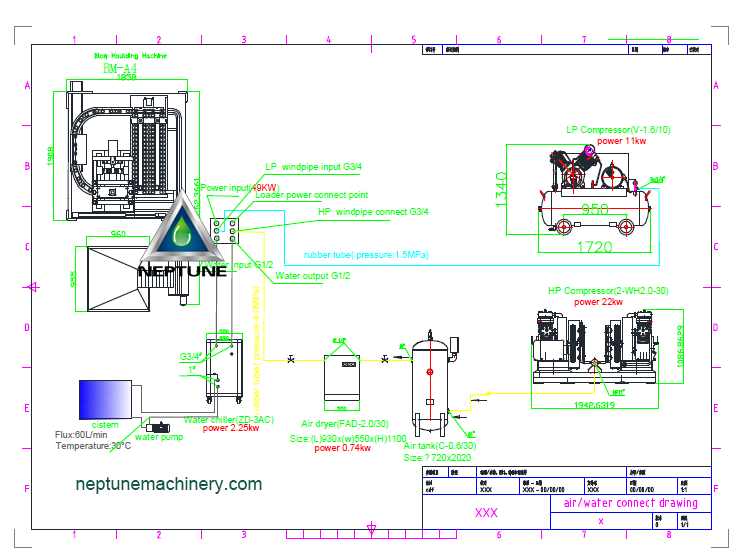

Our goal is to ship our customer orders during the same business day. Extrusion Blow Molding Machine Parts Name And Function Extruder. It acts as a source of heat for heating the plastic granules to the molten state.

Extrusion blow molding stretch blow molding and injection blow molding. Plstic Injection Molding Machinery. Ice lolly tube blowing machine.

Specific Product Blow Molding Machine. Auxiliary Machine And Mould. Specific Product Blow Molding Machine.

Processing of plastic blow moulding raw materials mainly plasticizing plastics. The metal shape of a manufactured product that fits on the platens of a blow molding machine and contains the plastic under pressure while it cools into the final part shape. American Holt has developed many replacement parts for Sidel blow molding machines including blocks sleeves pinion rods spacers bushings and knuckles.

108 rows Blowing Machine Spare Parts bravan2 2020-12-16T0235510000 Project. Extrusion blow molding is the largest of the three followed by stretch blow molding and injection blow molding. Multi-million dollar spare parts inventory.

The mold should have a fine matte finish to allow air to vent quickly and the parison to conform to the mold surface while it is still hot. Once the machine has created the parisons the next step of the blow molding process can begin. In general there are three main types of blow molding.

Specifications are 02ml05ml1ml2ml3ml5ml10ml Etc. Parts of Blow Moulding Process. This is the most common type of blow molding and is used to manufacture large quantities of relatively simple parts.

Smaller motor makes bigger power. New Name in Blow Molding Machinery Promises Gains for Dairy Bottles Reciprocating-screw machines and impact trimmers get energy-saving electric drive and quick-change features. Plugged or inadequate vents n Clean plugged or dirty vents particularly those along the parting line.

Servo Blow Molding Machine. PP PVC ABS TPE. When you need parts or service you can call our service line.

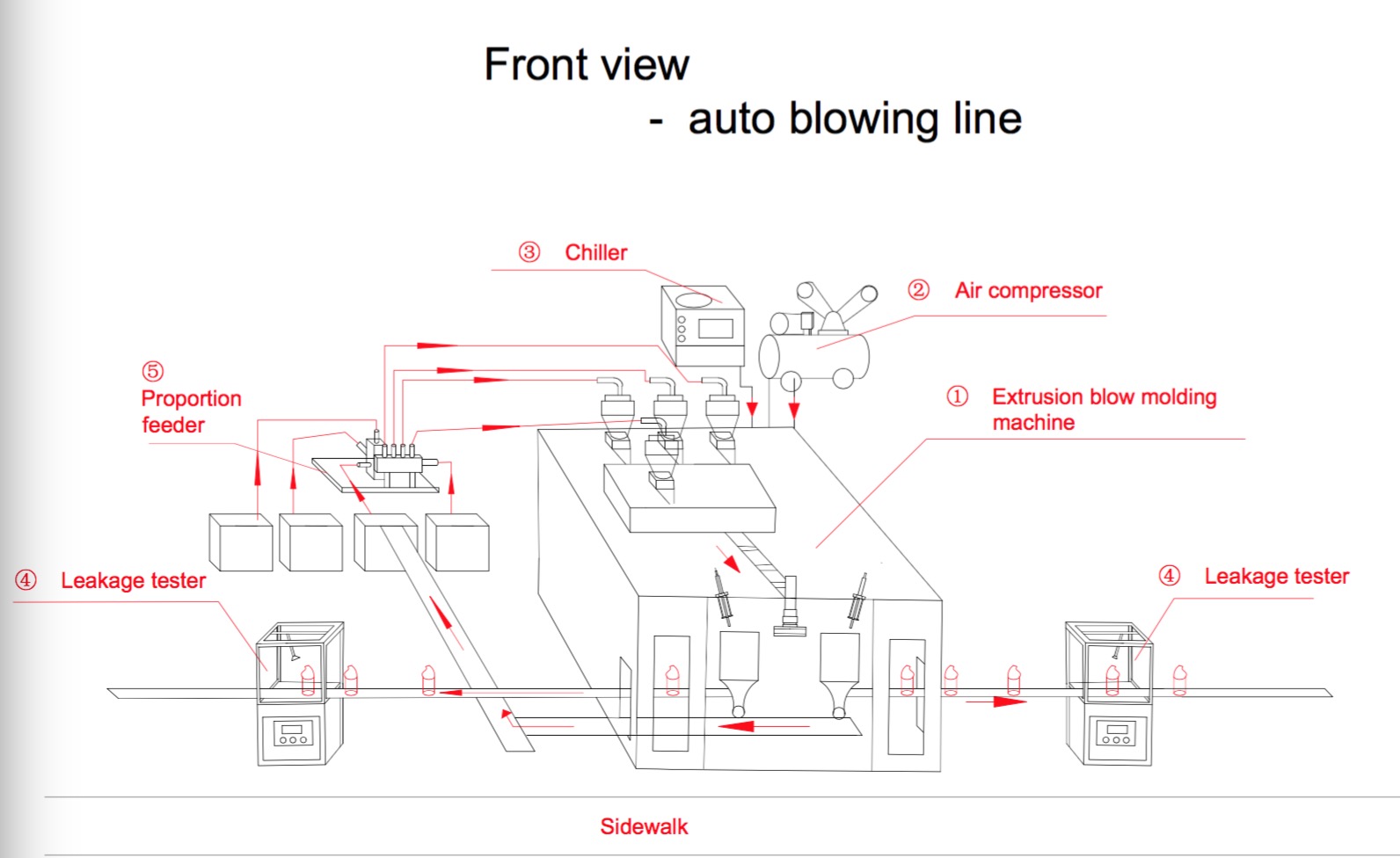

According to product specifications and customers requirements for production capacity you can choose single die head double die head three die head and. Immediate availability of spare parts conversion kits and accessories. The total blow molding industry is growing.

PCABSLCPPPPVC Plastic Injection Machine. Look no further PlastiWin Capital Equipment has you covered. By the use of hopper the plastic granules are to be poured into the moulding machine.

Extrusion blow molding injection blow molding and injection stretch blow molding. Service and Parts available 247 for Blow Molding Machines. Horizontal Plastic Injection Molding Machine.

Blow molding covers three main thermoplastic processes. Each machine can be modified and upgraded when needed. Leshan full electric extrusion blow-molding machine is of more energy saving and higher accuracy.

The feed from the Extruder. The core component of the. Looking for used injection blow molding machine parts for sale.

The parisons will form the base of the extrusion blow molding process no matter what type of bottle part or container you are creating. Our company occupy an area of 8000 square meters and annual production capacity currently stands at more than 200 sets. This machine adopts PLC man-machine system hydraulic forming system simple operation stable operation high precision high efficiency and energy saving and the parts can be branded.

Lower costs barter high efficiency. All parts of the eco-friendly extrusion blow-molding machine is full-electric controlled which means lower energy consumption. Trained and experienced employees with access to original design information of your machine.

It is also used for forming glass bottles or other hollow shapes. Belcher in Applied Plastics Engineering Handbook 2011 161 Introduction. The thermoplastic granules are to be used in the Injection Moulding Machine to create solid components.

Hand Operated Blow Moulding Machine Parts And Function Youtube

4000bph Automatic Blow Molding Machine

Extrusion Blow Molding Maintenance

Extrusion Blow Molding Find Suppliers Processes Material

Extrusion Blow Molding Machine Parts Name What Do Parts For The Machine

Blow Molding An Overview Sciencedirect Topics

Extrusion Blow Molding An Overview Sciencedirect Topics

2 Minutes To Know Blow Molding Technology

Two Methods Of The Blow Molding Process Blog Kb Delta

Blow Molding Machine Market Growth And Share By 2026

Extrusion Blow Molding An Overview Sciencedirect Topics

Injection Blow Molding An Overview Sciencedirect Topics

Abs Auto Moto Rear Spoiler Blowing Mould Car Spolier Extrusion Blow Molding Mold Making Machine Buy Abs Spoiler Blow Molding Machine Abs Spoiler Blow Mould Machine Abs Spoiler Making Machine Product

Extrusion Blow Molding Machine Parts Name What Do Parts For The Machine

Abs Auto Moto Rear Spoiler Blowing Mould Car Spolier Extrusion Blow Molding Mold Making Machine Buy Abs Spoiler Blow Molding Machine Abs Spoiler Blow Mould Machine Abs Spoiler Making Machine Product

Product Design Extrusion Blow Molding Machine Parts And Functions